BOOTHS

X-Change Powder Booth Systems

The Ideal Booth for Multiple Color Applications

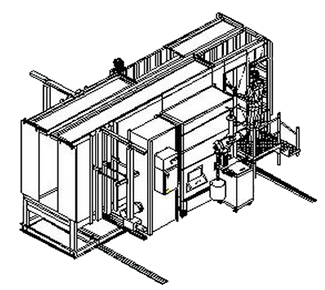

The versatile X-Change Powder Booth System has a collection of system flexible enough to adapt to any future needs with the capability of a Cartridge and the Conventional Cyclone Booth. The innovative Cyclone Module System can be outfitted with either type of powder recovery process. The users can configure the system to satisfy their powder recovery requirements now and in the future.

The efficiency and convenience of a Cartridge Booth with the flexibility of a Cyclone Booth... Recycle all low volume colors.

The Cyclone Module Powder Booth system combines the efficiency and compactness of a cartridge filter booth with the flexibility of a cyclone booth. The Cyclone Module Booth is specially designed for the multiple color coater using one or two major colors and a multitude of low volume and special colors which can be recycled or sprayed to waste. The most efficient usage of high volume colors is with a Cartridge Collector Module for each color. These roll-away, dedicated color X-Change Collector Modules yield nearly 100% usage of the powder coating and cross-contamination free color changes, since there is no cyclone or ducts to clean. The X-Change Collector Module recycles the powder directly to the internal hopper that feeds the guns. The X-Change Cyclone Module Booth gives the multiple color user the flexibility of spraying to waste another color in the middle of a color run and return to the previous color without cleaning the cyclone or duct work. The process is as simple as loading the second color, cleaning the powder guns, flushing the over-spray inside the spray enclosure into the cyclone inlet and change the booth airflow from cyclone to scrap airflow. After spraying the second color the guns are changed back to the original color, the second color over-spray is flushed-out, and the booth airflow is returned to cyclone mode to resume recycling the original color.

X-Change Multiple Module Booth System

Powder Recycling Process with the Cyclone Module Booth

The powder is sprayed into the booth tunnel enclosure by either manual or automatic spray equipment. The plant air that is drawn through the operator and work openings carries the powder over-spray cloud horizontally inside the enclosure and into the powder recovery system. The powder is either recycled through the dedicated colour Collector Module or through the Cyclone Module which in itself has two distinct powder paths: cyclone recovery or directly to waste. The clean air that is drawn through the primary filtration system is regulated by the volume control damper and flows into the fan inlet. The fan discharges the air through the final filters back into the plant.

In Collector Mode, the powder is drawn through the air and distribution baffles and deposited on the cartridge filter.

There it is automatically dislodged by a reverse-pulse of compressed air. This momentary snap of air allows the powder to fall into the single, removable hopper under the cartridges where it mixes with the fluidized virgin and recycled powder. This unique, closed loop powder recovery system design ensures a consistent blend of powder deposition throughout the operation. The virgin make-up powder is loaded into the collector through the load chute above the hopper. The chute also allows for the inspection of the powder level and fluidization in the hopper. The chute also allows for the inspection of the powder level and fluidization in the hopper. The Integral Hopper can be outfitted with either the Gun Feed Pumps or Recycle Pumps for transferring the recycled powder to the External Gun Feed Hopper located at the rear of the Collector when the optional Rotary Screener is used.

In Cyclone Mode, the powder over-spray is drawn toward the collector and can be diverted in two distinct paths

Directly into the Scrap Collector Module (where all powder over-spray is scrapped), or through a very short duct into the Cyclone Module (where all the powder is separated from the air stream for reuse). The recycled powder is collected in the plastic bin receiver under the cyclone where it can be continuously transferred to the external Gun Feed Hopper or manually removed at the end of the color run. The plastic bins can be used to store popular colors without cleaning them each time. The exhaust air and powder "Fines" from the Cyclone are ducted to the Scrap Collector Module for further filtering. The Scrap Collector Module is attached to the booth, similarly to the Collector Module, and has cartridge filters which when pulsed release the scrap powder into the internal waste powder bin hopper. This powder is collected for proper disposal.

Cyclone and Scrap Collector Module

The Booth can be outfitted with a Cyclone Collector Module for the recycling of low volume powders. The Cyclone Module assembly attaches to the booth in the place of a regular Collector Module. The Cyclone recycles the powder to a hopper assembly under the cones. The Cyclone vents the ultra-fine particles to a Scrap Collector Module that attaches to the Cyclone and the booth. The Cyclone Module is designed for rapid color change and has break-apart construction and easy to clean surfaces. The Cyclone Module is designed to feed the guns directly from the Recycle Hopper under the cyclones. The hopper can be equipped with a vibratory screener to filter out fibrous particles and debris.

The X-CHANGE Cyclone Module Booth gives the multi-color user the following flexibility:

- The use of dedicated Cartridge Collectors for high volume colors or specialty powders.

- Inter-changeability between dedicated color Collectors and Cyclone powder recovery.

- Recycle any color back to the automatic or manual gun feed hopper.

- Spray to waste in the middle of a color run. The dual airflow capability allows the operator to change colors being sprayed in the middle of a color run by isolating the cyclone airstream and diverting the airflow directly to the Scrap Collector and return to the original color after a simple cleaning of the contaminated booth aras and gun, hoses and powder source.

- Use as a spray to "waste" booth without any powder recovery.

- Fast color change: The recycle hopper is a plastic bin that comes with a cover for storing popular colors without any cleaning.

- The cyclone cones assembly is caster mounted and can be cleaned if required.

- The powder intake chamber has access from three sides for complete cleaning.

- The cyclone air spirals are movable for quicker change-over and less cleaning.

- The exhaust air is ducted directly to the collector with improved airflow, no chamber to clean, and minimization of contamination.

- Single lever cyclone and hopper clamping, and simple strap latching for the cyclone and collector.

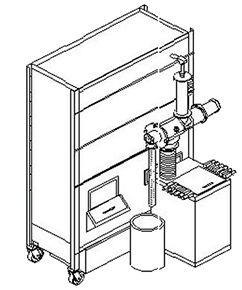

Cyclone Module

X-CHANGE Cyclone Module: The Cyclone Module is the primary powder separator. the modular assembly has the following features:

- Caster mounted assembly:Extra large, swivel casters: 6" diameter on the frame, 4" diamter on the cone frame and multiple vertical stainless steel break-apart Mini-Cyclones, removable Recycle Hopper with Vibrator, easy to clean stainless steel construction with access doors on air plenum, ductless design that does not require explosion relief vent.

- Cyclone Mobile Frame: Caster mounted assembly with stainless steel intake plenum that opens for complete cleaning of the powder chamber and the cyclone spin scrolls and the cyclone tubes. The unit features a single handle clamp system for latching the cyclone cone assembly as well as the recycle hopper.

- Spin-Out Cone Mobile Frame: Caster mounted assembly with stainless steel cyclone spin-out cones that separates from the cyclone frame for complete cleaning of the cones and the discharge flange over the recycle hopper.

Cyclone Scrap Collector Module

X-CHANGE Scrap Cartridge Collector: The Scrap Collector Module is the after-filter for the ultra-fine powder particles not captured by the cyclone. The design allows the collector to filter the air after the cyclone or directly from the booth interior in spray to scrap mode with the following features:

- Secure Latching: The collector is attached to the booth with a quick release strap-latch.

- Integral Scrap Hopper: The waste powder is collected for proper disposal in the bin hopper. The Waste Transfer Pump is side mounted with regulator and gauge controls. The hopper is removable from the rear of the collector.

- Dual Airflow: Recycle and Waste spray airflow air passages for optimum flexibility. The removable door panel directs directs the airflow to the cyclone in recycle mode or directly to the collector in spray to waste mode.

- Exceptional Powder Filtration: Multiple horizontal extended surface polyester media cartridge filters for high volume operation, which are a single piece design and are washable. The filters are removable from the exterior of the collector. The seal is on the clean side of the tube sheet; a feature that ensures a better seal that is easy to inspect and proper tightening the filters.

- Waste Transfer Pump and Receiver Assembly: The waste powder is directly fed through a hose to a Receiver that is mounted on the "Scrap" powder drum. The Separator vents back to the Collector.

- Segregation Damper: Damper is closed by the fire detection system if required, or manually by the operator.

- OSHA Safety Vent Assembly: Mounted on Collector roof if required when the system is in "Scrap" Mode.

- Made to Last: Extra large, 6" diameter swivel casters, heavy gauge powder coated steel construction. Unit is shop assembled prior to shipping.