PYROSTRIP

Pyro-Strip Tank System

With the PYRO-STRIP Tank System, the abrasive action of fluidized sand joins extreme temperatures to clean your hooks and racks in record time economically! Fluidized sand cleaning is the method of choice for its economical and ecological excellence. The equipment being fabricated is a proven technology with safe and simple operation, and robust construction required for hard working paint lines. Steel, iron and bronze parts can be stripped, as well as aluminum for recycling. Invigorating hot sand bath vaporizes paint, powder coatings and crusty ash residue in 1/6 the time of conventional burn-off furnaces, without the post cleaning clean-up. At the same time, Pyro-Strip is 100% environmentally safe, and 500% more efficient than conventional methods. The PYRO-STRIP Fluidized Sand Tank System is a European design being fabricated in Chicago, employing American equipment standards and domestically available components. The unit is available with either the low profile lid or the H-C lid which allows the entire basket to be loaded and the lid closed prior to fluidizing the sand, thus eliminating any escape of smoke into the plant. Pyro-Strip machines are fully tested before being shipped to their final destinations where our technicians supervise installation and train your staff.

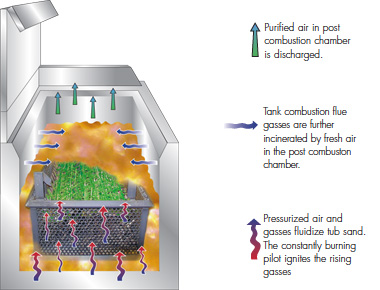

Pyro-Strip Operation

Compressed air mixed with gas fluidizes the calibrated quartz sand, burning and scrubbing the residue from the product. The organic residue itself acts as fuel, reducing the amount of added gas necessary to complete the combustion of the coatings. The vaporized residues rise to the surface of the sand, where they are further incinerated in a bed of flame. In this combustion zone, oxygenation raises the temperature to nearly 1600 degrees F. The purified flue gasses rise into the Post-Combustion chamber and are expelled. The unit can be quipped with an optional entegra cyclone separator for further cleansing of the flue gasses.

Pyro-Strip Process

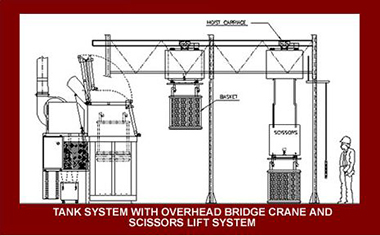

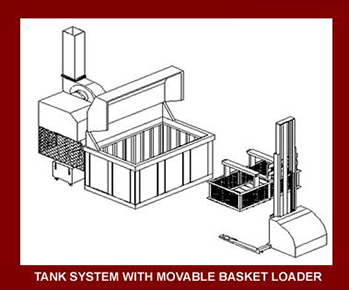

The parts are loaded into a basket that is then hoisted into the tank where the fluidized hot sand scrubs and burns off the organic material and vaporizes it without damaging or warping the work pieces. The cleaning cycles take from 20 to 40 minutes at a temperature of 800 to 850 deg. F. The time cycle is regulated by the mass of the load and amount of organic material to be removed. The basket of cleaned parts is lifted with the hoist out of the tank and set to cool. The work pieces in most cases may be ready to use on the line with little or no post-cleaning, depending on the coating build-up and process parameters. The bubbling action of the sand removes most loose ash coating from the surface.

Hook Cleaning System

The Pyro-Strip fluidized sand tank system utilizes a special compressor to fluidize the calibrated quartz sand inside the tank. The fluidizing air, premixed with the combustion gas, then burns on the surface of the sand bath by a constant burning pilot. The combustion gas supply is modulated in accordance with the heat energy generated by the burning of the oragnic materials, which is absorbed by the sand, thus reducing fuel consumption.

- Features!

- Rugged construction

- Fast cleaning cycles

- Will not damage hooks

- Uniform product cleaning every time

- Cleaner hooks!

- Advantages!

- Reduces operation cost

- Reduces fuel cost

- Reduces risk of explosion

- Maintenance free

- Enviormentally friendly

- Energy saving design!